Measurements from Sounding Pipes and Tank Calibration Tables help shipping companies track, regulate, and manage their inventory of oil, petroleum, chemicals, or any other liquid asset, that is stored in a tank.

Tank Calibration Tables (Sounding & Ullage) are charts, indicating the volume of liquid inside a tank at a specific level. Traditionally, the tanks measurements are taken manually, using a steel tape or steel strap via the Sounding Pipes or with more advanced methods, implementing technologies like radar or ultrasonic gauges. Sounding pipes lead down to, almost, the bottom of a tank to enable the depth of liquid to be measured by a sounding tape. The sounding pipes end above freeboard deck in easily accessible places and are fitted with efficient, permanently attached, metallic closing appliances.

It is essential to obtain accurate measurements of the stored liquids volume, but without correct calibration tables, even the best automatic gauging systems and the most accurate manual measurements are of little value. Thus, erroneous Sounding measurements or Calibration Tables lead to technical/operational issues, with extra time needed for measurement verifications, effecting financially the Shipowner and leading to uncertainties of the liquid volume stored inside the relevant tanks.

A known issue, that the calculated volume from Sounding pipe measurements may not apply to the existing liquid volume values of the Tank Calibration (Sounding/Ullage) Tables, is the incorrect arrangement or fabrication of the Sounding Pipe. That might occur during the construction and shipbuilding process or due to other reasons.

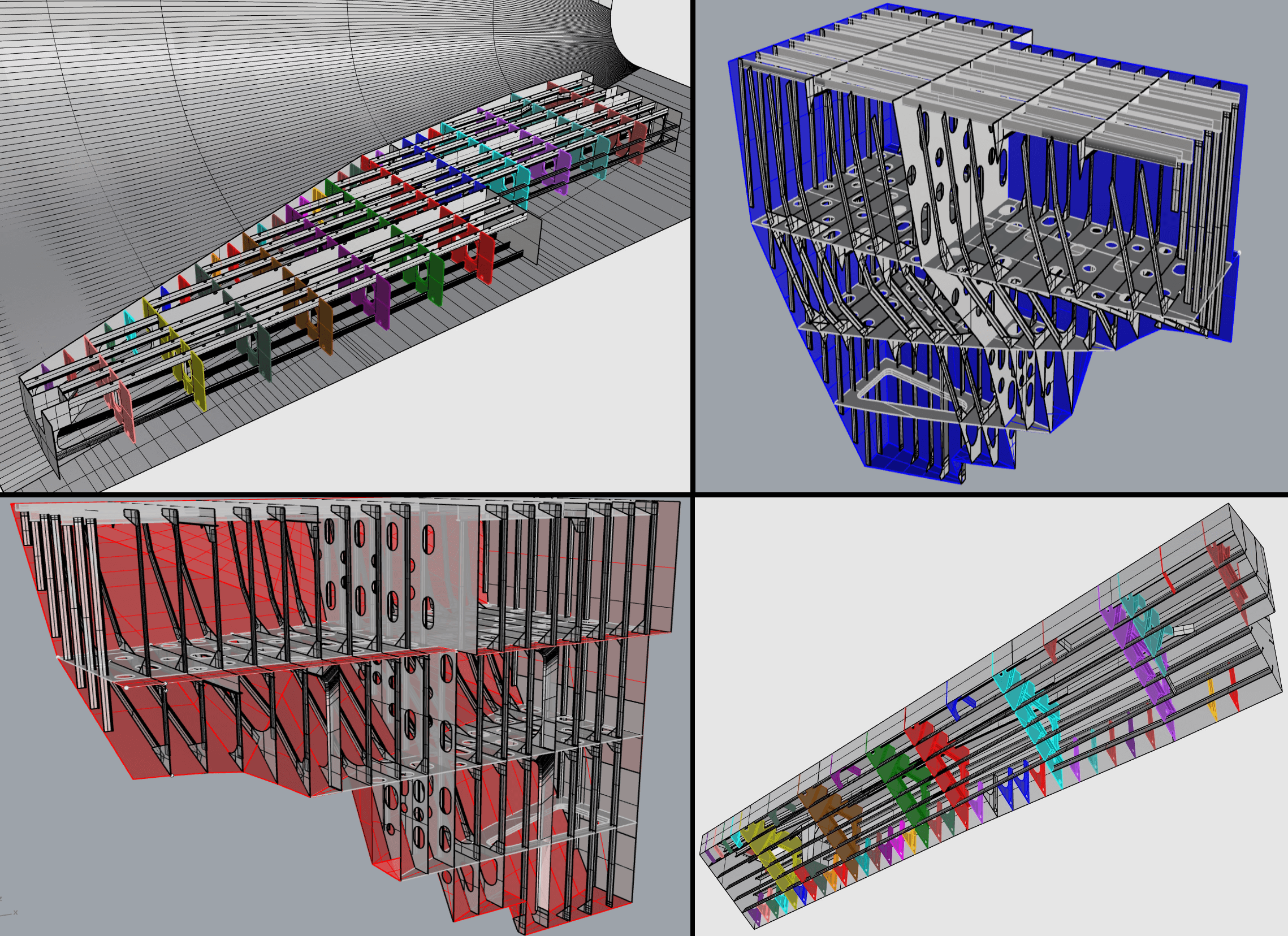

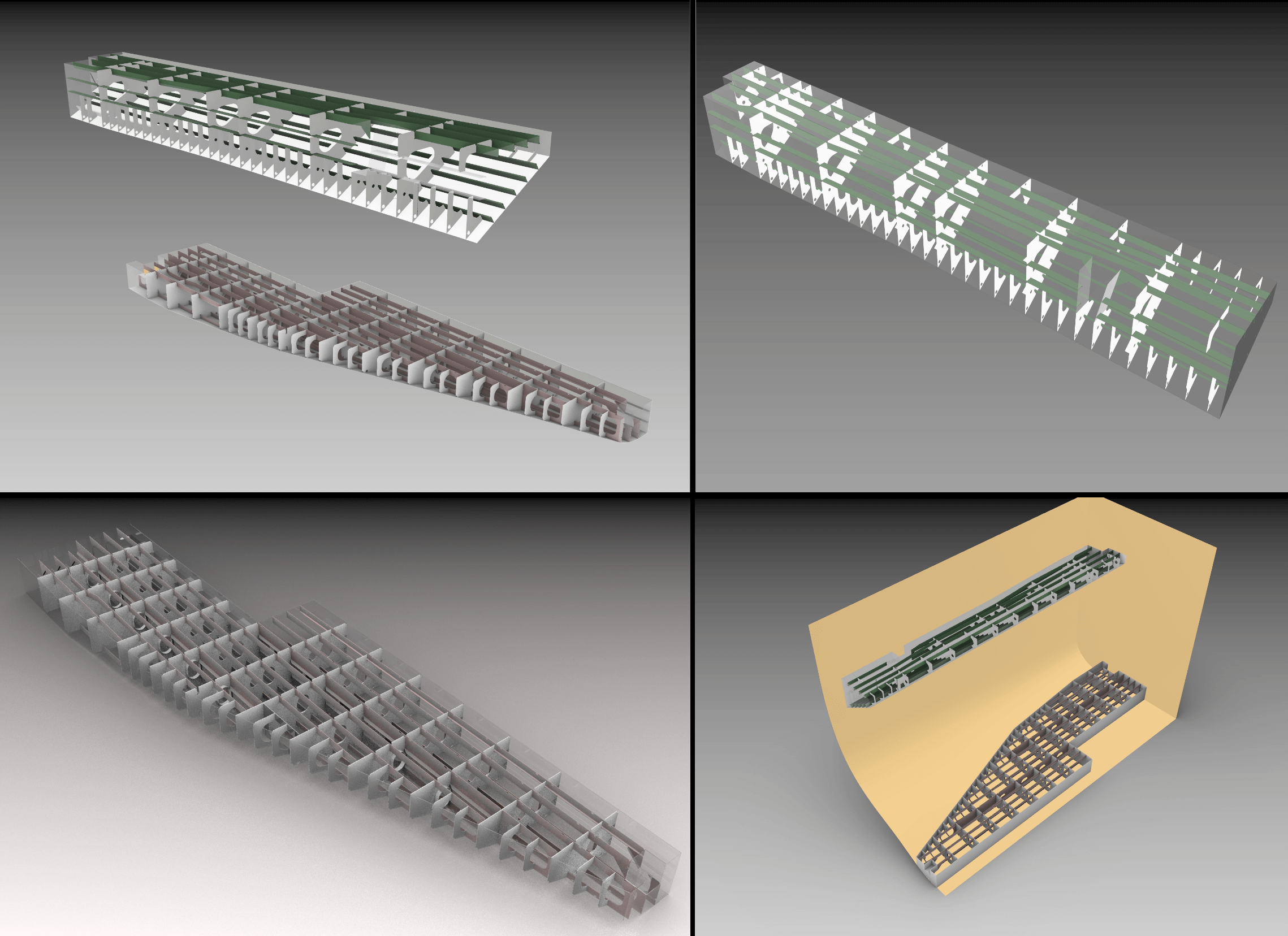

Naval-DME, guarantees the complete 3D Modeling of all vessel’s tank structural elements in detail (Girders and Frames modelled with openings, Brackets, Plates, etc.) and Sounding Pipes, using the vessel’s Lines Plan, Construction drawings and Isometric drawings. If Construction drawings or Isometrics cannot be provided by the owners or the vessel, then Naval-DME recommends an on-site survey, to measure and record the as-build sounding pipe arrangement, by scanning the tank with the use of certified equipment.

In case the Tank pipe, the Sounding pipe and the construction drawings are provided by Owner, but also, an on-site survey is performed, then our team of Naval Architects can compare the received drawings to the as-built arrangement and produce a more accurate 3D Model of the Tank.

After the completion of the 3D Modeling, the Tank Calibration Tables will be calculated and produced with the help of respective Software. Tank Calibration Tables results can be prepared, presented, and delivered in hard copy and electronic format.